Industry 4.0

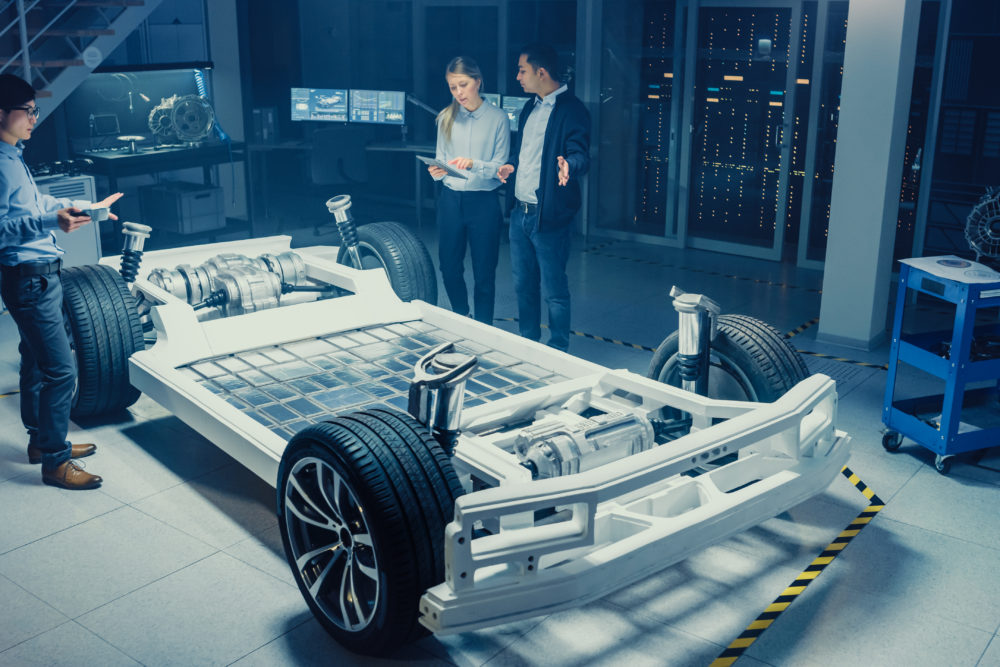

We transform factories controlled by Excel and paper into fully digitized and flexible smart factories. Everything runs digitally, with data available immediately and wherever it is needed. Thanks to this, there are significant time savings, material savings and savings on human resources. Digitization means reducing the possibility of human error to a minimum.

More than 100 customers

More than 100 customers around the world have used our services and methodology for implementing a paperless smart factory. To digitize production processes, we use the most suitable systems based on analyzes and feasibility studies such as SAP, Productoo and others. The solutions designed by us have been used by customers from Automotive, Pharma, Food & Beverages and other industries. Our systems manage production in large multinational corporations as well as in medium-sized manufacturing companies in the Czech Republic and Slovakia.

Show a digitized factoryWhat can we digitize?

We usually digitize

Itica digitizes the entire production process door to door or only parts of it according to the specific requirements of the client. We implement the latest production strategies and technologies. In this way, we help with the individual stages of your business and production activities.

We use many years of experience with production management based on SAP analysis and optimization to participate in the development of the modern Productoo smart ecosystem.

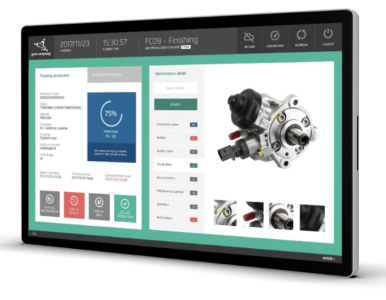

Digitized Shopfloor

Your production operators (workers) have a production plan available directly on the line, they can call a maintenance person or view the production process. All in digital form and in the language of their choice.

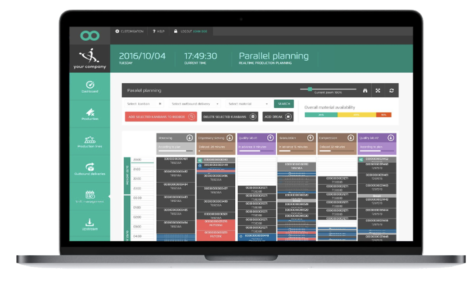

Paperless production planning

Planners create a plan on their computer or tablet screen, and changes are instantly reflected on the monitors of the rest of the factory. One planner can create and flexibly change the production plan of an entire factory of, for example, 1000 people.

Mobile maintenance 4.0

Maintenance technicians are always available anywhere, and on their tablets they can see maintenance jobs sorted by priority and available spare parts.

.

.

.

.

Examples of our Digitization Projects